Every vessel’s ship safety equipment begins with its people — and protecting those people starts with proper maritime PPE. From welding PPE and gloves to flame-retardant suits and respirators, personal protective equipment shields seafarers from the daily hazards of shipboard life.

Whether you’re performing hotwork on deck, cleaning tanks, or maintaining engines, having the right gear ensures compliance with maritime safety rules and safeguards every operation.

In this guide, you’ll learn:

- What types of PPE are required onboard under SOLAS and MARINA

- The difference between industrial safety equipment and maritime PPE

- How to inspect, maintain, and document PPE for audits

- The role of vendors and safety gear suppliers in certification and replacement

>> Download Now: [Free Ship Safety Equipment Compliance Checklist (PDF)]

Understanding PPE in Ship Safety Equipment

Personal Protective Equipment (PPE) is the first defense layer in any safety system. Under the ISM Code and MARINA Circulars, every vessel must maintain an updated PPE inventory and inspection record.

Unlike land-based industrial safety equipment, maritime PPE is designed to endure salt corrosion, humidity, and confined-space conditions.

The Safety Officer and Master are responsible for ensuring that all gear—helmets, gloves, masks, harnesses—is certified, logged, and accessible at the workplace.

Remember: Properly maintained PPE not only protects lives but also demonstrates full compliance during Port State Control (PSC) or RightShip inspections.

Types of Maritime PPE Used Onboard

1. Head and Face Protection

- Hard hats and bump caps guard against falling tools or swinging blocks.

- Welding helmets with dark lenses protect eyes from ultraviolet flashes.

- Face shields defend against flying particles during grinding or chipping.

Tip: Replace any helmet or visor that has suffered impact or UV fading—these are common PSC deficiencies.

2. Eye and Respiratory Protection

- Safety goggles and anti-fog glasses for deck maintenance.

- Respirators and dust masks during painting, tank cleaning, or welding.

- For gas-detector or firefighting operations, use certified SCBA sets maintained by authorized safety gear suppliers.

These items link directly to your vessel’s maritime fire safety plan.

3. Hand and Body Protection

- Oil-resistant gloves for engine tasks.

- Heat-resistant gloves for hotwork and welding.

- Flame-retardant overalls or boiler suits meeting ISO 11612 standards.

Ensure PPE fits correctly; ill-fitting gloves or sleeves can cause entanglement.

4. Fall and Hearing Protection

- Safety harnesses with shock-absorbing lanyards when working aloft or overside.

- Earplugs or earmuffs to reduce engine-room noise exposure.

All equipment must be marked, tagged, and inspected monthly by the Safety Officer.

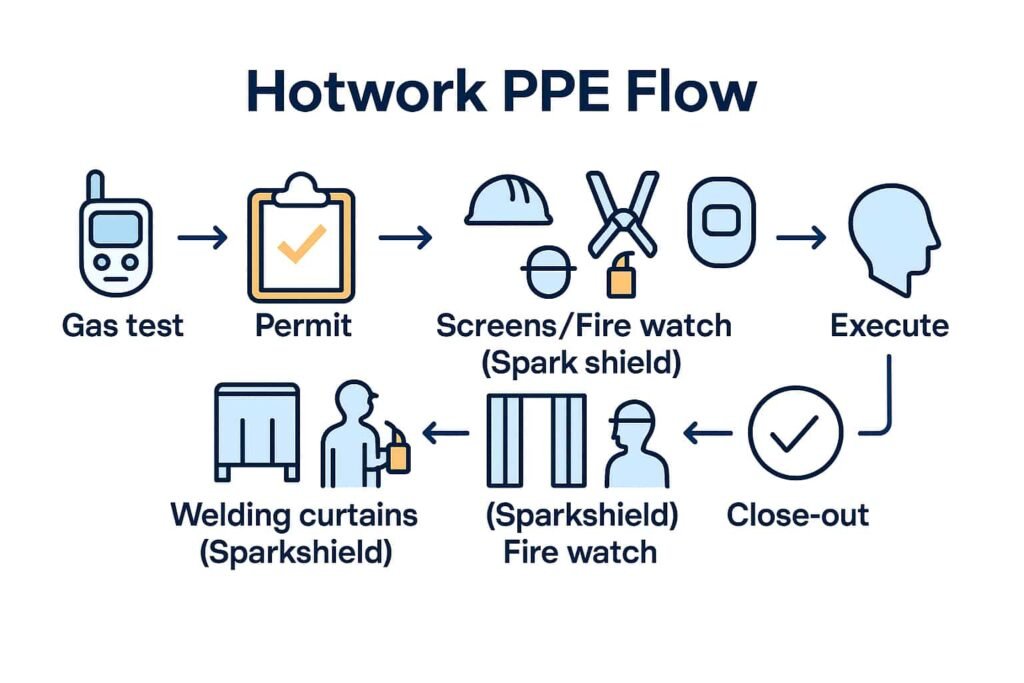

Hotwork remains one of the highest-risk shipboard activities. To protect welders and crew:

- Wear auto-darkening welding helmets rated for UV and infrared protection.

- Use leather aprons, flame-resistant gloves, and arm guards.

- Ensure welding screens or curtains protect nearby personnel.

- Follow maritime safety rules—obtain a Hotwork Permit, conduct gas testing, and have firefighting appliances ready.

“Every successful weld starts with safety.”

PPE Inspection, Storage, and Record-Keeping

A well-maintained record proves compliance and reduces audit stress.

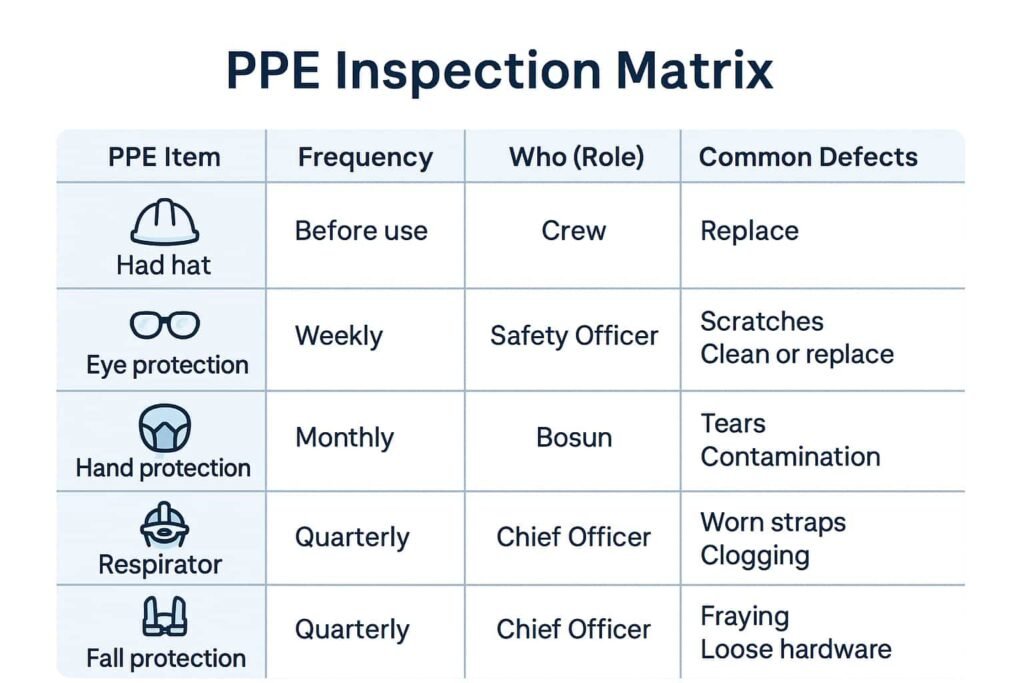

| PPE Type | Inspection Frequency | Responsible Crew | Remarks |

| Welding Helmet | Monthly | Safety Officer | Replace cracked visors |

| Gloves | Weekly | Bosun | Dispose if torn or oil-soaked |

| Harness | Monthly | Chief Officer | Check stitching & carabiners |

| Respirator | Before use | Crew | Replace filters regularly |

Store PPE in dry, ventilated lockers, clearly labeled and segregated by type. Damp or sun-exposed storage degrades materials quickly.

Use this matrix every month to standardize inspections—who checks what, how often, and what to do when defects are found.

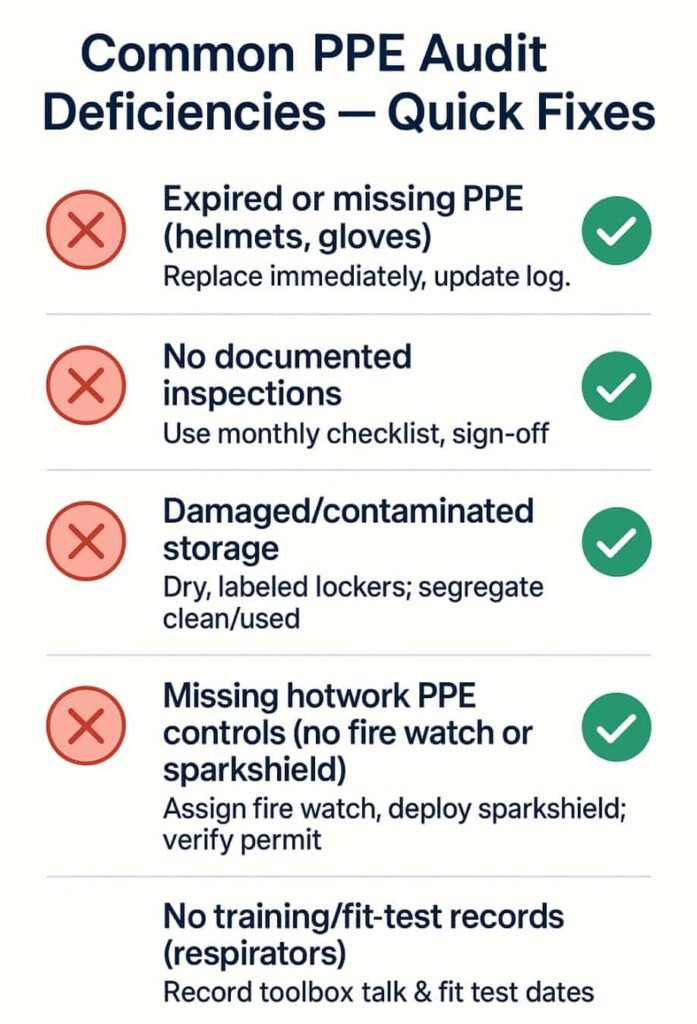

Common PPE Deficiencies Found During Audits

Auditors frequently report:

- Missing or outdated PPE registers.

- Torn gloves or faded coveralls still in use.

- Expired welding mask certifications.

- Lack of crew familiarization records.

- Shared gear without cleaning documentation.

Avoid these by training crew on replacement intervals and logging every inspection in your SMS forms.

Integrating PPE with Other Ship Safety Equipment

PPE works hand-in-hand with the vessel’s maritime fire safety and marine rescue equipment systems.

During drills, seafarers must wear the proper combination of gear—fire suits for FFA exercises, marine life jackets during abandon-ship drills.

This integrated approach ensures both proactive and reactive protection, forming the core of your maritime safety equipment strategy.