Ship safety equipment forms the backbone of every vessel’s protection system—ensuring the safety of crew, cargo, and the ship itself.

From marine life jackets and rescue boats to maritime PPE and fire-fighting appliances, these systems are not just accessories—they are mandatory lifelines defined by maritime safety rules under SOLAS, MARINA, and the ISM Code.

In this comprehensive guide, you’ll learn…

- how to categorize and maintain your safety systems,

- understand inspection intervals,

- and choose reliable safety gear suppliers who meet international standards.

Whether you manage a bulk carrier, general cargo ship, or coastal vessel, this article will help you keep your ship safety equipment compliant, organized, and always audit-ready.

What Is Ship Safety Equipment and Why It Matters

Every seafarer relies on properly maintained equipment to respond effectively during an emergency. Ship safety equipment encompasses all systems and gear designed to prevent incidents, protect life, and aid survival at sea. This includes:

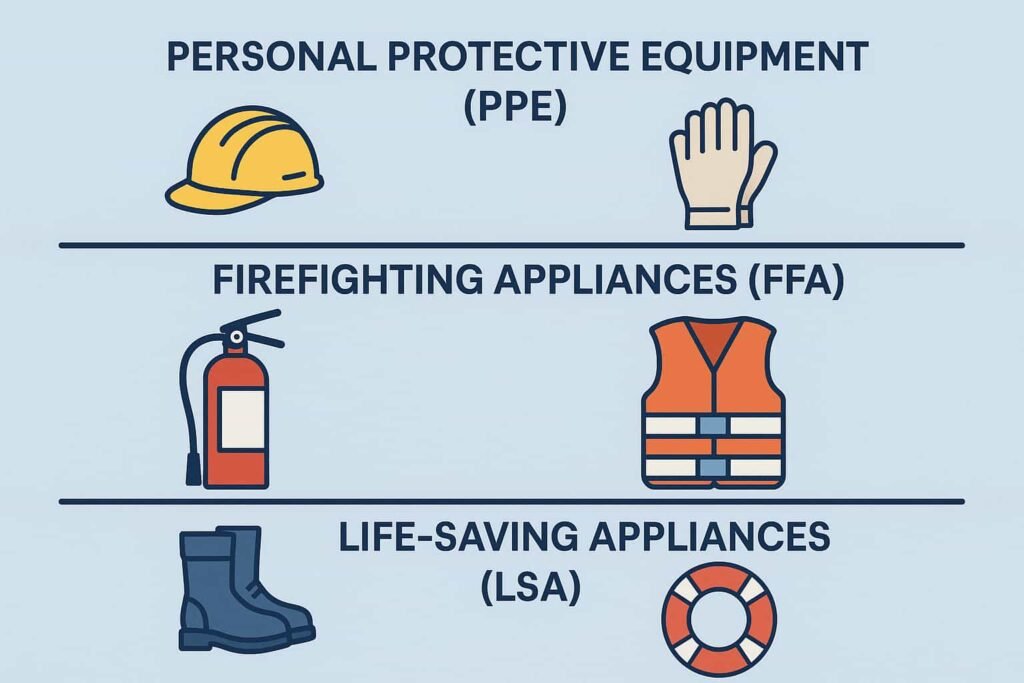

- Personal Protective Equipment (PPE): Helmets, gloves, welding PPE, safety boots, and harnesses used for industrial and deck operations.

- Fire-Fighting Appliances (FFA): Extinguishers, hydrants, fire hoses, CO₂ systems, and detection alarms.

- Life-Saving Appliances (LSA): Marine life jackets, rescue boats, life rafts, EPIRBs, and immersion suits.

“Compliance isn’t optional—it’s an obligation under maritime safety equipment regulations such as SOLAS Chapters II-2 and III, and MARINA Circulars for vessel certification.”

Main Categories of Ship Safety Equipment

Personal Protective Equipment (Maritime PPE)

Every operation onboard—from hotwork in the engine room to mooring on deck—demands the right maritime PPE.

This includes welding PPE, flame-retardant coveralls, face shields, gloves, and ear protection. Unlike industrial safety equipment used ashore, maritime PPE must withstand salt exposure, humidity, and confined-space conditions.

Tip: Maintain a PPE register and inspection record under your SMS. Replace damaged gear immediately and conduct toolbox meetings before high-risk tasks.

>> Further Reading: 5 Essential Maritime PPE for Enhanced Crew Protection

Fire-Fighting Appliances (FFA)

Maritime fire safety depends on preventive maintenance and crew readiness. Typical shipboard FFA includes:

- Portable and fixed extinguishers (CO₂, foam, and dry-powder)

- Fire pumps, hydrants, and hoses

- Smoke/heat detection systems and control panels

Under SOLAS II-2, these must be inspected monthly and pressure-tested annually by certified safety gear suppliers. Crew should perform weekly checks of alarms and pumps, ensuring full system readiness.

>> Further Reading: 7 Essential Tips for Maritime Fire Safety for Ship Owners

Life-Saving Appliances (LSA)

When all else fails, LSA keeps the crew alive. This category covers marine rescue equipment such as life rafts, marine safety gear like lifeboats and immersion suits, and signaling devices such as EPIRBs and SARTs.

LSA is governed by SOLAS III and MARINA’s annual inspection requirements. Records of drills, raft servicing, and inventory must be logged and available for any audit.

Maritime Safety Rules and Standards

Maritime administrations and classification societies enforce strict maritime safety rules to ensure vessels remain safe and seaworthy. Key references include:

| Regulation | Category | Inspection Frequency |

| SOLAS II-2 | Fire-Fighting Appliances | Monthly / Annual |

| SOLAS III | Life-Saving Appliances | Weekly / Monthly |

| MARINA Memo 2025 | PPE & Industrial Safety | Quarterly |

| ISM Code 10.2 | All Equipment | Annual Verification |

Following these standards also strengthens performance in PSC and RightShip inspections.

Inspection and Maintenance of Ship Safety Equipment

Routine inspection keeps equipment functional and compliant. A structured schedule should include:

| Equipment Type | Check Interval | Record Form |

| PPE | Daily / Job-Based | PPE Register |

| FFA | Monthly / Annual | Fire Safety Log |

| LSA | Weekly / Monthly | LSA Checklist |

Combine regular checks with clear documentation—auditors look for consistency more than perfection.

Choosing Reliable Safety Gear Suppliers

Your compliance is only as strong as your vendors. When sourcing ship safety equipment, ensure your safety gear suppliers can:

- Provide MARINA and ISO 9001 certifications.

- Offer warranty, calibration, and after-sales service.

- Deliver genuine parts with traceability numbers.

- Supply documentation for class verification.

Partnering with trusted industrial safety equipment and maritime PPE providers guarantees both quality and audit security.

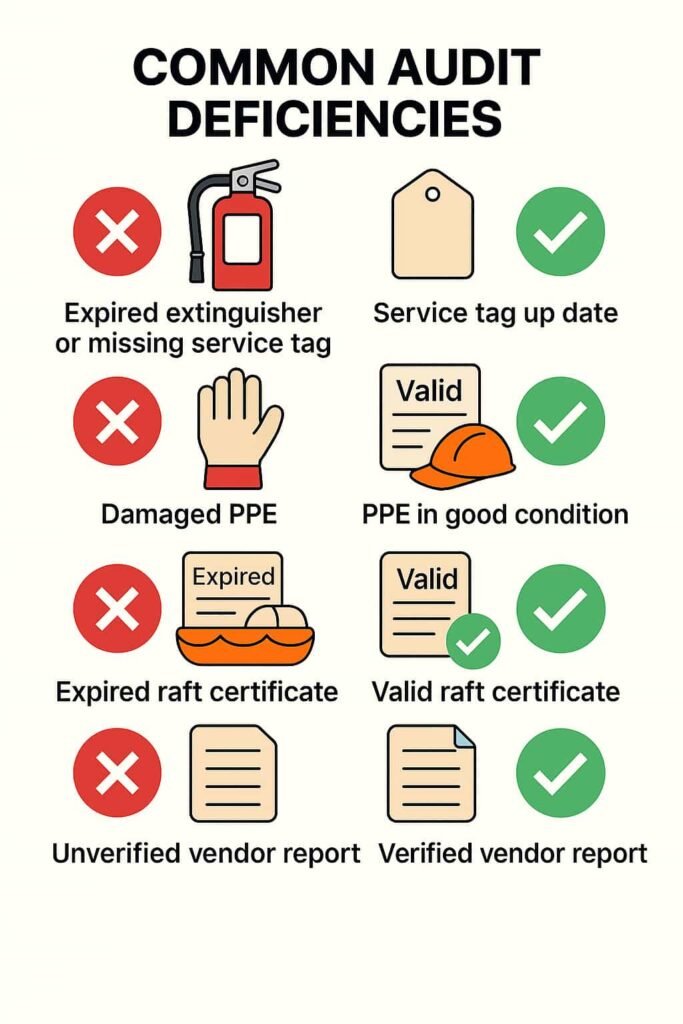

Common Audit Deficiencies (and How to Avoid Them)

Typical findings during inspections include:

- Expired extinguishers or missing service tags.

- Damaged or unrecorded PPE.

- Inoperative lifeboat hooks or expired raft certificates.

- Unverified vendor servicing reports.

Avoid these by maintaining checklists, crew training logs, and up-to-date vendor certifications in your SMS records.