Why a Structured PMS Matters

A Planned Maintenance System for ships (PMS) is the backbone of safe and efficient operations. When it’s weak, small issues multiply: jobs go unchecked, parts fail unexpectedly, and non-conformities (NCs) appear during audits.

A poorly maintained PMS can mean missed maintenance on safety-critical systems, unclear responsibilities, and inconsistent evidence — all red flags during RightShip, Class, or Port State inspections.

A structured PMS, on the other hand, creates traceability. Every task is planned, performed, verified, and recorded.

It connects maintenance with ISM Code compliance, keeps the ship inspection-ready, and strengthens the link between reliability, efficiency, and safety.

Step 1 — Understand the PMS Framework

A Planned Maintenance System is a structured method of ensuring that all equipment and systems onboard a vessel are serviced, inspected, and maintained at defined intervals to prevent breakdowns and maintain compliance.

Unlike corrective maintenance, which responds after a failure occurs, or predictive maintenance, which relies on condition monitoring and trend data, PMS focuses on scheduled actions. Its purpose is prevention — identifying and addressing issues before they escalate.

Regulatory foundations:

- ISM Code, Section 10 — mandates maintenance of the ship and equipment according to planned arrangements.

- Classification Society Rules — outline inspection and testing requirements for machinery, hull, and safety systems.

- Flag State Circulars — often provide additional PMS guidance for statutory items.

Frameworks and Expectations

Classification societies, Flag States, and vetting organizations share one expectation: every maintenance activity must be planned, verified, and recorded.

For example:

- Class wants proof that equipment essential to class remains in serviceable condition.

- Flag ensures statutory items (lifesaving, firefighting, pollution prevention) are regularly checked.

- RightShip and OCIMF MEG4 require PMS traceability — showing that preventive maintenance directly supports safe mooring, propulsion, and cargo operations.

Together, these frameworks form the foundation for building a compliant and reliable PMS.

Step 2 — Build the PMS Architecture

A solid PMS isn’t just a list of jobs. It’s a structured workflow that connects assets, tasks, schedules, and records.

Core Components of a PMS

A complete PMS typically includes five core elements:

| Component | Purpose |

| 1. Asset Register | Identifies all maintainable items and systems onboard. |

| 2. Task Library | Lists maintenance actions derived from manuals and regulations. |

| 3. Intervals | Defines how often each task is done — by running hours or calendar. |

| 4. Approvals & Roles | Assigns who performs, verifies, and approves work. |

| 5. Records | Provides evidence for audits and internal verification. |

Example Flow

Asset Register → Task Library → Intervals → Approvals → Records

Each stage feeds the next — when the process is consistent, it ensures traceability from planning to verification.

💡 Tip: Keep the workflow visual. A simple flow diagram posted in the engine control room or maintenance office helps crew understand where each PMS action fits in the bigger picture.

Step 3 — Creating the Asset Register

In PMS terms, an Asset is any maintainable item — machinery, system, or equipment — that requires scheduled maintenance.

To build an accurate Asset Register:

- Gather source documents:

- Class-approved equipment lists

- Maker’s manuals

- Dry-dock and service reports

- Previous PMS exports (if available)

- Categorize logically:

- Group by system → subsystem → component.

- Tag criticality:

- Identify essential items for safety, propulsion, navigation, and pollution prevention.

Sample Table – Asset Register Structure

| Equipment | Tag No. | Location | Criticality | Remarks |

| Main Engine | ME-001 | Engine Room | High | Include fuel pump set |

| Steering Gear | SG-001 | Steering Flat | High | SOLAS Reg. V/26 item |

| Bilge Pump | P-02 | Pump Room | Medium | Verify auto mode |

| Emergency Generator | EG-001 | Upper Deck | High | Test start weekly |

💡 Tip: Always cross-check your Asset Register with Class certificates and ISM Form “Record of Safety Equipment.” Missing an asset can lead to non-conformity during audits.

Step 4 — Building the Task Library

The Task Library transforms your asset list into actionable work. Each task defines what needs to be done, how, and what the expected outcome is.

Sources of tasks:

- Manufacturer’s manuals: Contain preventive maintenance and inspection steps.

- Class & Flag requirements: Include periodic tests (e.g., emergency generator weekly test, lifeboat lowering every 3 months).

- Company or ship-specific tasks: Custom routines added after incidents or past findings.

Example Task Entries

| Equipment | Task | Frequency | Verification |

| Steering Gear | Check alarm system (audible & visual) | Monthly | Verify both alarms active |

| Main Engine | Clean fuel oil filter | 1,000 hrs | Record ΔP and remarks |

| Lifeboat | Inspect fall wire condition | 3 months | Record with photo evidence |

| Oily Water Separator | Function test | Monthly | Record ppm reading |

Best Practices:

- Use clear, action-oriented task names (“Inspect”, “Test”, “Replace”, “Verify”).

- Define expected results or acceptance criteria.

- Include safety notes if the task involves isolation or PPE requirements.

💡 Tip: Poorly worded tasks cause confusion. “Check generator” means nothing — “Inspect generator brushes for wear and clean carbon dust” is traceable and verifiable.

Step 5 — Setting Intervals and Scheduling Logic

The heart of PMS planning lies in interval selection. Set intervals that are practical, regulatory-compliant, and aligned with actual vessel operations.

Choosing Intervals

- Running Hour-Based: Ideal for engines, pumps, compressors — tracked via hour meters.

- Calendar-Based: Used for safety equipment, deck fittings, and systems rarely run continuously.

- Condition-Based: Triggered by inspection results (e.g., vibration, oil analysis).

- Event-Based: Linked to dry-dock, survey, or annual testing cycles.

Example Table – Scheduling Intervals

| Equipment | Task | Interval | Basis |

| Main Engine | Inspect fuel pumps | 1,000 hrs | Running hours |

| Lifeboat Winch | Function test | 3 months | Calendar |

| Air Compressor | Drain moisture trap | Weekly | Calendar |

| Emergency Fire Pump | Run test | Weekly | Calendar |

If using PMS software, intervals auto-update after completion. For Excel or manual PMS, establish a Job Due Log showing next due dates.

⚙️ Tip: Avoid overloading. Too many daily tasks dilute focus. Prioritize critical equipment first, then expand gradually.

Step 6 — Define Roles, Approvals, and Evidence

Assign Responsibilities

Each PMS task must have clear ownership — from execution to verification.

| Role | Responsibility | Approval Level |

| Chief Engineer (C/E) | Executes and verifies technical tasks | Final approval for engine jobs |

| 2nd Engineer (2/E) | Assists and records evidence | Verifies completion |

| Master | Oversees and signs off on critical items | Safety-related approvals |

| Technical Superintendent | Audits and reviews overall PMS | Office verification |

Consistency in who signs what prevents audit confusion.

Evidence That Stands Up to Inspection

Inspectors and auditors don’t just want to see “Done.” They want proof.

Acceptable evidence includes:

- Dated job cards signed by responsible officer

- Photos showing before/after condition

- Calibration certificates (for instruments)

- Running hour logs or trend charts

Mini-Checklist – Acceptable PMS Evidence

- Job description clearly matches completed work

- Date, signature, and rank of person performing the job

- Supporting photo or test result attached

- Linked to equipment ID or tag number

- Stored in both ship and shore database

💡 Tip: Use a consistent naming format for digital evidence:

ME_Pump_Inspection_2025-10-01.jpg — easy to retrieve and cross-reference.

Step 7 — Implementing and Maintaining the PMS

Implementation is best done gradually. Start small, ensure consistency, then scale.

- Pilot Rollout: Begin with the Engine Department — typically better record discipline.

- Familiarization: Conduct onboard orientation for officers on how to log jobs and attach evidence.

- Data Synchronization: Ensure the ship’s PMS syncs with the shore office database or cloud.

- Review Cycle: Update after dry-dock, Class survey, or new equipment installation.

⚙️ Tip: Treat PMS setup as a “living system.” Every modification, new machinery, or regulatory update must reflect in the PMS immediately — not after the next audit.

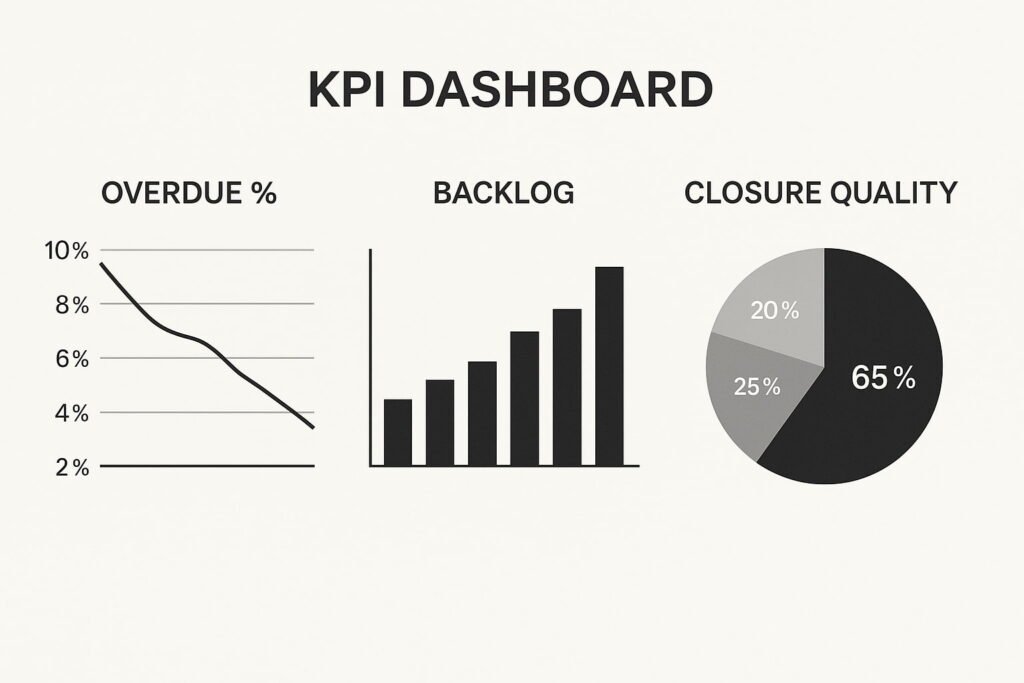

Step 8 — KPIs, Monitoring, and Continuous Improvement

A PMS is only as good as the results it produces. Establish Key Performance Indicators (KPIs) to monitor its effectiveness.

Sample PMS KPIs

| KPI | Formula | Target |

| Overdue % | (Overdue tasks ÷ Total tasks) × 100 | < 5% |

| Backlog Trend | Count over 3 months | Decreasing |

| MTBF (Mean Time Between Failures) | Hours between breakdowns | Increasing |

| Closure Quality | Verified evidence ÷ Total closed | > 90% |

Hold a monthly PMS review with the Technical Superintendent to discuss:

- Overdue causes (spares, manpower, weather)

- Repeated failures or near misses

- Lessons learned after dry-dock

Mini Dashboard Template

| Month | Overdue % | Backlog | Remarks |

| July | 3% | 12 | On track |

| August | 7% | 25 | Spare delay |

| September | 2% | 10 | Improved |

💡 Tip: Display KPI charts in the engine control room — visual data motivates crew to close tasks on time.

Common Pitfalls and How to Prevent Them

Even well-intentioned PMS setups can fail if poorly managed. Here are five frequent pitfalls — and how to avoid them:

| Pitfall | Why It’s a Problem | Prevention |

| Overloading with too many tasks | Crew cannot cope, leading to false entries | Start small; expand gradually |

| Poor naming conventions | Confusing tasks, unclear verification | Use standardized action verbs |

| No link between job cards & evidence | Auditors question traceability | Attach proof to each record |

| Ignoring overdue analysis | Repeated backlogs and findings | Review overdue log monthly |

| Inconsistent record format | Difficult to verify trend | Use one PMS template fleet-wide |

Summary Checklist — Step-by-Step PMS Setup at a Glance

- Create Asset Register

Tip: Start with critical systems first — propulsion, steering, safety.* - Build Task Library

Tip: Extract directly from maker’s manual for authenticity.* - Assign Intervals

Tip: Align with dry-dock and survey cycles.* - Define Roles & Approvals

Tip: Keep signatures consistent per rank.* - Record Evidence

Tip: Combine photo + signed job card = strong proof.* - Monitor KPIs and Improve

Tip: Review monthly with Superintendent and crew.*