A planned maintenance system is only as strong as the tasks and intervals you define.

In this practical guide, you’ll lock in realistic schedules, clean evidence, and audit-ready records without the fluff.

What you will learn:

- How to source tasks from manuals, Class/Flag, and vetting feedback

- The right interval logic (calendar, running hours, condition-based)

- Building an equipment-by-equipment task library with IDs and priority tags

- Evidence that passes audits (job cards, photos, certificates, logs)

- Handling exceptions, deferrals, and approvals the right way

- Monthly review tactics to kill backlogs and tighten reliability

- Quick starter tables for ME, AUX gen, steering, electrical, LSA/FFA, and pollution systems

Why Task and Interval Planning Defines a Strong PMS

A Planned Maintenance System lives or dies by how well its tasks and intervals are defined.

If you load the PMS with vague jobs or unrealistic frequencies, you’ll get backlogs, rushed work, and non-conformities.

Tighten the plan, and the whole ship tightens with it: predictable workloads, clean logs, and evidence you can show at any audit without breaking a sweat.

This connects directly to your PMS setup steps and the overall framework, so you’re building on solid ground from day one.

>> See the full Ship Planned Maintenance: Complete Guide to a Reliable PMS Onboard

Gathering Source Material for Task and Interval Setup

Where PMS Tasks Come From

- Equipment manuals & maker recommendations (primary reference for running-hour and condition-based tasks)

- Class & Flag requirements (statutory items you must never miss)

- Statutory regulations: SOLAS, MARPOL, LSA/FFA Codes (define tests, drills, and proof)

- Company experience & vetting feedback (turn repeat findings into scheduled tasks)

Common Data Sources to Consolidate

| Source | Example Use | Verification Method |

| Maker manual | Running-hour tasks | Compare with last service report |

| Class/Flag list | Statutory items | Match with latest approval |

| Vetting findings | High-risk repeat items | Review the last inspection report |

Tip: Create a one-pager per equipment item that compiles the manual extracts, last service dates, and any inspection comments. It shortens your planning time and speeds up superintendent reviews.

Building the Task Library by Equipment Type

Structuring Your Library

- Categorize tasks by equipment type and system.

- Assign a unique ID or code for traceability (e.g., ME-FUEL-001).

Flag tasks as Statutory (S) vs Non-statutory (N) to prioritize the schedule and get audits right.

Main Equipment Categories (Core PMS Sections)

- Main Engine

- Auxiliary Engines / Generators

- Steering Gear and Deck Machinery

- Electrical Systems

- Life-Saving Appliances (LSA) and Fire-Fighting Appliances (FFA)

- Pollution Prevention Equipment

- Sensors, Calibration, and Test Instruments

>> See the full Ship Planned Maintenance: Complete Guide to a Reliable PMS Onboard

Example Task and Interval Tables by Equipment

Each table below shows Task Description | Interval | Basis | Evidence. Use these as seed entries and tailor to your ship’s maker guidance, service history, and risk profile.

Main Engine

| Task Description | Interval | Basis | Evidence |

| Inspect fuel pumps and linkages | 1,000 hrs | Running hours | Job card + date-stamped photo |

| Overhaul cylinder head | 12,000 hrs | Running hours | Overhaul report & parts list |

| Verify alarms and safety trips | Monthly | Calendar | Log entry + photo proof |

Mini-notes:

- Tag engine protection trips as critical; do not defer without superintendent sign-off.

- Cross-check head overhaul intervals against SFOC trends and scavenge drain observations.

Auxiliary Engines / Generators

| Task Description | Interval | Basis | Evidence |

| Clean turbocharger and air filters | 2,000 hrs | Running hours | Job card + photos |

| Check AVR and voltage settings | 3 months | Calendar | Calibration certificate |

Mini-notes:

- Sync tasks with load cycles (peak hotel loads vs sea passages).

Tie in fuel quality notes (water/sludge findings) to justify earlier air-side cleaning.

Steering Gear and Deck Machinery

| Task Description | Interval | Basis | Evidence |

| Test steering gear alarms | Weekly | Calendar | Bridge log entry |

| Inspect hydraulic lines for leaks | 6 months | Calendar | Photo proof |

| Function test windlass and mooring winches | Monthly | Calendar | Deck log + checklist |

Mini-notes:Combine with mooring line inspection (MEG4) to catch tails/lines near discard criteria. Keep photos of measured diameters, elongation, and splices in the same evidence folder.

Electrical Systems

| Task Description | Interval | Basis | Evidence |

| Inspect switchboard for loose terminals | Monthly | Calendar | Inspection sheet |

| Battery voltage and electrolyte check | Weekly | Calendar | Record sheet |

| Test emergency lighting | Monthly | Calendar | Job card |

Mini-notes:

- Align with safety inspections (emergency lighting tests often coincide with drill prep).

- Use thermal imaging quarterly on MCCs if previous hot-spots were reported.

Life-Saving Appliances (LSA) and Fire-Fighting Appliances (FFA)

| Task Description | Interval | Basis | Evidence |

| Test lifeboat engine start | Weekly | Calendar | Log entry |

| CO₂ system functional test | Annually | Calendar | Inspection report |

| Fire pump pressure test | 3 months | Calendar | Pressure reading record |

Mini-notes:

- Observe Class/Flag retention requirements for service providers and keep photos of gauge readings, seals, and bottle weights in the folder.

Pollution Prevention Systems

| Task Description | Interval | Basis | Evidence |

| OWS 15-ppm alarm test | Monthly | Calendar | Test record |

| BWTS operation test | 3 months | Calendar | Operation log |

| Incinerator inspection | 6 months | Calendar | Job card + report |

Mini-notes:

- These are high-risk for PSC/RightShip findings; keep before/after photos, trend screenshots, and any maker support emails.

Sensors, Calibration, and Test Instruments

| Task Description | Interval | Basis | Evidence |

| Calibrate pressure gauges | Annually | Calendar | Calibration certificate |

| Check gas detectors | Monthly | Calendar | Verification record |

| Verify temperature sensors | 6 months | Calendar | Calibration sheet |

Mini-notes:When outsourcing calibration, save the vendor’s certificate, scope, and instrument serials with the PMS job card to maintain traceability.

Defining Intervals and Managing Exceptions

Start with the maker’s recommendation. Adjust only when evidence supports the change—e.g., heavier usage, aging equipment, adverse oil analysis, or updated OEM guidance.

When spares are delayed, record the exception, justify mitigation, and set the catch-up plan.

Use criticality tagging to focus resources:

- High: Steering Gear, Main Engine, CO₂ system

- Medium: Deck Crane, Generator

- Low: Accommodation Fans

Tip: Don’t silently extend intervals. Add a PMS revision note with the reason, data (e.g., vibration readings), and approval.

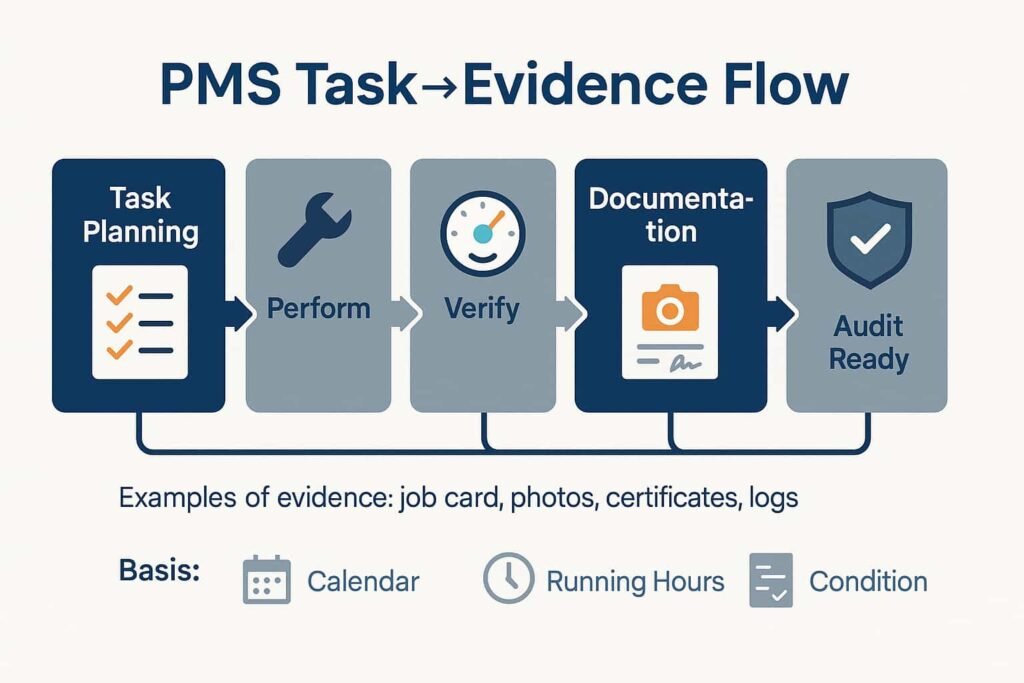

Linking Tasks to Records and Evidence

Every PMS entry should tie to verifiable records—no orphan tasks. Keep a clear, consistent folder/database structure so inspectors can trace work without hand-holding. Example patterns:

- /Main Engine/Overhaul_12000hr_2025-06-10/JobCard.jpg

- /FFA/CO2_Test_2025-08-01/Certificate.pdf

Naming tips:

- Prefix with system and task; suffix with date (YYYY-MM-DD).

- Standardize photo naming (e.g., 1_Before.jpg, 2_During.jpg, 3_After.jpg).

- Capture signatures (digital or scanned) for job cards; avoid unsigned evidence.

Monthly Review and Continuous Improvement

At month-end, pull a PMS Summary Sheet: due/overdue tasks, reasons (weather, spares, manning), and any recurring delays.

During superintendent review, look for patterned backlogs and adjust intervals or manpower.

This is also where you ensure critical tasks remain on track and that evidence quality (photos, certificates, logs) is consistent.

>> See the full Ship Planned Maintenance: Complete Guide to a Reliable PMS Onboard

Summary Table — Equipment, Tasks, and Evidence Snapshot

A compact one-page cheat sheet you can print and pin in the ECR/CCR.

| Equipment Category | Example Tasks (Shortlist) | Typical Evidence (Keep Together) |

| Main Engine | Fuel pump/linkage inspection; Cylinder head 12k-hr overhaul; Safety trips verification | Job cards, dated photos, overhaul report, parts list |

| Aux Engines/Gen | Turbo/blower & air filter cleaning; AVR/voltage checks | Job cards, photos, calibration certificates |

| Steering/Deck | Steering alarm test; Hydraulic line leak check; Windlass/winch function test | Bridge/Deck logs, photos, leak checklists |

| Electrical | Switchboard terminal inspection; Battery checks; Emergency lighting tests | Inspection sheets, record sheets, job cards |

| LSA/FFA | Lifeboat start test; Fixed CO₂ yearly functional; Fire pump pressure testing | Log entries, FFA service/CO₂ inspection reports, readings |

| Pollution Prev. | OWS 15-ppm alarm test; BWTS operations test; Incinerator inspection | Test records, operation logs, job cards + service reports |

| Sensors/Calib. | Pressure gauge calibration; Gas detector check; Temperature sensor verification | Calibration certificates, verification records, calib sheets |

Tip: Turn this table into a monthly dashboard by adding a column for “This Month Status” (Done / Overdue / N/A). It keeps everyone honest.