Why Ship Planned Maintenance Matters

A ship’s Planned Maintenance System (PMS) isn’t just another compliance formality. It’s the pulse of vessel reliability — the difference between predictable performance and costly downtime.

In modern shipping, every voyage is a test of readiness, and PMS is the framework that keeps machinery, records, and crew aligned toward that single goal: safe, efficient, and verifiable operation.

The ISM Code makes it mandatory. Class societies and flag states demand it. But beyond compliance, a reliable PMS protects your budget and your reputation.

It prevents breakdowns, improves spare part forecasting, and helps your vessel sail through vetting and Port State inspections with confidence.

In every audit, a planned maintenance system PMS onboard tells a story — not just about equipment, but about discipline. It shows whether your crew understands the link between maintenance, safety, and operational integrity.

Understanding the Planned Maintenance Framework

What Is Ship Planned Maintenance?

Planned maintenance is proactive. It differs from corrective maintenance, which reacts after a failure, and from predictive maintenance, which relies on condition monitoring tools to anticipate one. PMS is the backbone of consistency — the system that ensures a generator isn’t forgotten, a safety valve isn’t skipped, and a calibration isn’t delayed.

A reliable PMS is, in effect, a ship’s “memory.” It captures what was done, when, and by whom.

Regulatory and Industry Foundations

The ISM Code (Section 10) requires companies to establish procedures for planned maintenance, ensuring vessels are maintained “in conformity with relevant rules and regulations.” Every audit and inspection returns to this principle.

Class Societies (like ClassNK, DNV, ABS) reinforce it through surveys that verify PMS implementation. Flag States and Port State Control (PSC) check its consistency, while vetting inspectors under RightShip, OCIMF, or TMSA scrutinize how records are linked to actual maintenance actions.

PMS, therefore, sits at the intersection of regulatory compliance, technical reliability, and audit defensibility.

Core Structure of a Ship’s PMS

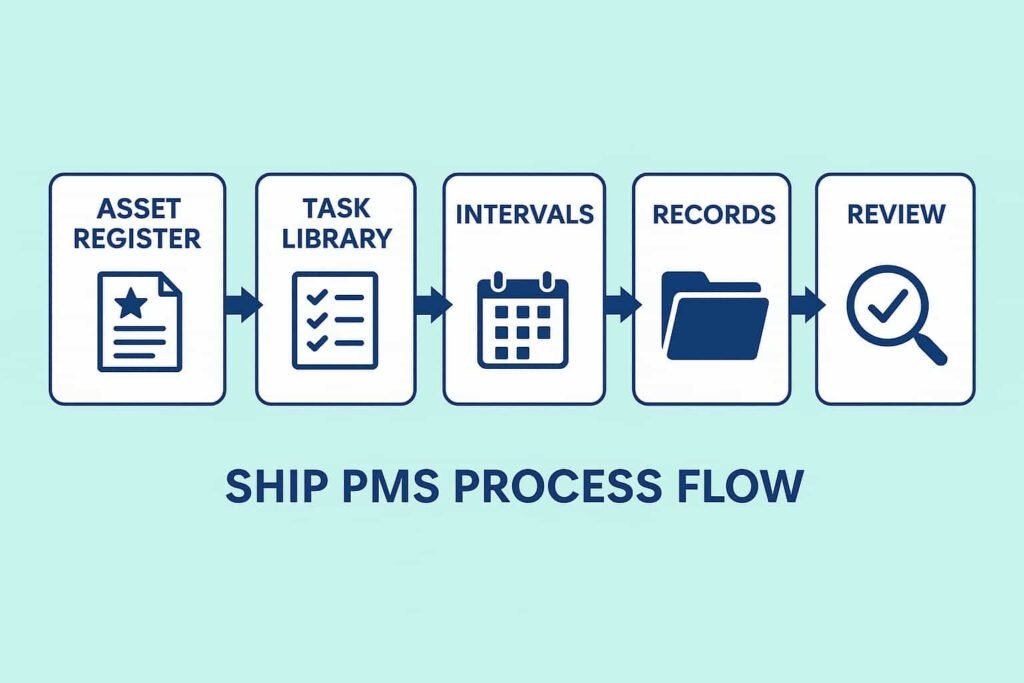

A strong PMS is built like a framework — each part feeding the next. Understanding this architecture is key to building or auditing your own.

From Asset Register to Records

A typical PMS structure flows like this:

- Asset Register – A complete list of shipboard machinery and equipment, each with a unique ID or tag number.

- Task Library – Maintenance tasks associated with each asset, aligned with OEM manuals, Class requirements, or company standards.

- Intervals and Scheduling – Time or usage-based triggers (running hours, calendar days, voyage-based) that determine when tasks fall due.

- Approvals and Roles – Defined responsibilities: who creates, approves, performs, and verifies each job card.

- Records and Evidence – Job cards, checklists, and supporting documents stored in logical structure and easily retrievable during inspections.

Simple PMS Flow Diagram:

Asset Register → Task Library → Intervals → Records → Review

This logical flow forms the backbone of a digital or manual PMS. When these links are consistent, inspections become straightforward and performance measurable.

Tasks and Intervals — The Beating Heart of Your PMS

The real work of maintenance happens here. Every engine, pump, and winch has its own rhythm — and PMS synchronizes those rhythms into a manageable schedule.

Some tasks are running-hour based (e.g., “Every 2,000 hours, overhaul the Main Engine fuel pump”). Others are calendar-based (“Inspect lifeboat release gear every 3 months”).

The challenge lies in balancing both — especially when ship schedules shift.

Start by grouping equipment into clear categories:

- Propulsion Systems: Main Engine, CPP, Stern Tube, Shaft Seals

- Auxiliary Systems: Generators, Boilers, Purifiers, Compressors

- Deck Equipment: Winches, Cranes, Windlass, Mooring Gear

- Safety & Life-Saving: Fire Pumps, Lifeboats, CO₂ System

Navigation & Communication: Gyro, Radar, GMDSS Batteries

Each category should have its task library, interval, basis of requirement, and evidence of completion — forming the four pillars of traceability.

The PMS doesn’t end at scheduling. It demands proof.

Each completed task should have evidence: photographs, calibration certificates, or signed checklists attached to its job card.

>> 3. Learn how to plan tasks and intervals by equipment with sample checklists and evidence guides.

Common Questions About Ship Planned Maintenance

1. What is ship planned maintenance and why is it important?

Ship planned maintenance ensures all vessel components operate smoothly in compliance with operational and safety standards, preventing costly breakdowns and ensuring reliability.

2. How does a planned maintenance strategy reduce ship repair costs?

A strong maintenance strategy minimizes unexpected repairs and extends the service life of shipboard equipment by identifying and addressing issues early.

3. What role does planned maintenance play in ship safety and compliance?

Effective planned maintenance promotes a culture of safety and compliance, essential for maintaining operational excellence and meeting industry regulations.

4. How often should a ship maintenance checks be done?

Regular planned maintenance checks should be conducted to detect potential issues before they escalate—protecting both the crew and the vessel from operational risks.

5. Can technology improve ship planned maintenance?

Yes. Integrating maintenance system pms onboard ships with modern technologies enhances monitoring, reporting, and data-driven decision-making across the vessel’s operations.

PMS Records and Audit Readiness

Why Records Matter

In an audit, inspectors don’t ask if you did maintenance — they ask where’s the proof. Records are the soul of PMS integrity. They connect every task to its verification, and every verification to a timeline.

Your PMS records should demonstrate:

- Traceability: Each job card links to its asset and schedule.

- Retention: Job records are stored for at least 3 years (longer for critical equipment).

- Consistency: File names and folders follow uniform conventions (e.g., “ME_JobCard_2025-04-18”).

- Verification: Supervisors sign off after physical checks.

- Cross-Reference: Calibration, permits, and class reports are attached where applicable.

When inspectors can trace an entire chain — Task → Job Card → Evidence → Verification → Retention — they see a system in control.

Preparing for Inspections

A PMS audit begins weeks before inspectors arrive. Having a repeatable T-14 to T-1 days routine makes all the difference.

Mini Pre-Inspection Checklist

| Day Range | Key Actions |

| T-14 to T-10 | Review PMS dashboard. Identify overdue or pending tasks. |

| T-9 to T-7 | Verify evidence attachments. Cross-check signatures and job card completeness. |

| T-6 to T-4 | Ensure calibration and safety equipment records are current. |

| T-3 to T-1 | Arrange documentation folders (digital or printed). Conduct internal review. |

| T-0 | Keep all records ready for inspector’s review and master’s briefing. |

By formalizing this routine, you transform audit prep from chaos to calm — and avoid last-minute document hunts.

>> 4. Learn how to organize PMS records for audit readiness and satisfy inspectors with confidence.

Troubleshooting and Continuous Improvement

Common PMS Failures

Even robust systems falter. The most common weak points in ship PMS include:

- Missing or inconsistent records — evidence not attached or wrongly labeled.

- Overdue tasks — especially those linked to port delays or machinery unavailability.

- Naming discrepancies — e.g., “ME FO Pump #1” vs. “Main Engine Fuel Pump A.”

- Unclosed job cards — marked “done” but lacking verification.

When these pile up, you face backlog clustering — multiple overdue or open jobs that compromise audit readiness and operational safety.

Practical Fixes and Backlog Reduction

Addressing PMS failures isn’t about blame; it’s about control. Here’s how to break the cycle:

- Categorize the backlogs — Critical (safety), Operational (machinery), or Routine (non-critical).

- Root Cause Analysis (RCA) — Identify if delay stems from spare parts, manpower, or process gaps.

- Implement CAPA — Corrective Action (fix now) and Preventive Action (avoid recurrence).

- Review cadence — Weekly reviews for operational backlogs, monthly for system-wide trends.

Over time, the PMS becomes not just a database but a feedback loop — learning from delays and improving predictability.

>> 5. Learn how to troubleshoot PMS backlogs and NCs to keep your system running smoothly.

Strengthening Your Ship Planned Maintenance Program

Empowering your crew with a solid understanding of ship planned maintenance leads to smarter, safer operations.

A reliable maintenance program combines training, documentation, and regular assessments. Encourage crew feedback to drive continuous improvement and ensure every task supports compliance and efficiency.

Stay proactive—schedule maintenance ahead of issues to keep equipment aligned with regulatory standards and operational goals.

Each vessel is unique, so tailor your maintenance plan to its specific needs. Finally, leverage real-time data for faster insights and better decision-making onboard.

KPIs and Review Cadence

Tracking PMS performance requires measurable indicators.

Here are the key PMS KPIs every superintendent or master should monitor:

| KPI | Definition | Target |

| Overdue Rate (%) | % of total tasks past due | ≤ 5% |

| Closure Quality (%) | Tasks with complete records & verification | ≥ 95% |

| MTBF (Mean Time Between Failures) | Time between equipment failures | Increasing trend |

| Backlog Trend | Direction of open tasks over time | Downward |

Create a monthly PMS dashboard showing these metrics. Trends reveal more than snapshots — they show whether discipline is embedded or slipping.

Fostering a culture that values ship planned maintenance encourages crews to spot issues before they become problems.

In the end, planned maintenance isn’t just about ticking compliance boxes — it’s about achieving true operational excellence and reliability at sea.

Building a Culture of Maintenance Discipline

Systems don’t maintain ships — people do.

A PMS is only as strong as the crew that uses it. Building a maintenance culture means:

- Embedding PMS training in onboarding and drills.

- Encouraging chiefs and engineers to treat job cards as operational logs, not paperwork.

- Rewarding accuracy, not just completion speed.

- Integrating feedback from near-misses and NCs into maintenance planning.

Leadership sets the tone. When masters and superintendents emphasize documentation quality, the crew follows — and the system sustains itself.

Glossary — Quick PMS Terms Explained

| Term | Meaning |

| MTBF | Mean Time Between Failures — measures equipment reliability. |

| NC | Non-Conformity — a deviation from required standards. |

| CAPA | Corrective and Preventive Action — structured response to NCs. |

| Asset Register | Master list of all shipboard equipment maintained under PMS. |

| LOTO | Lock-Out Tag-Out — safety procedure for isolating equipment during maintenance. |

| ISM Code | International Safety Management Code — global framework mandating maintenance systems. |